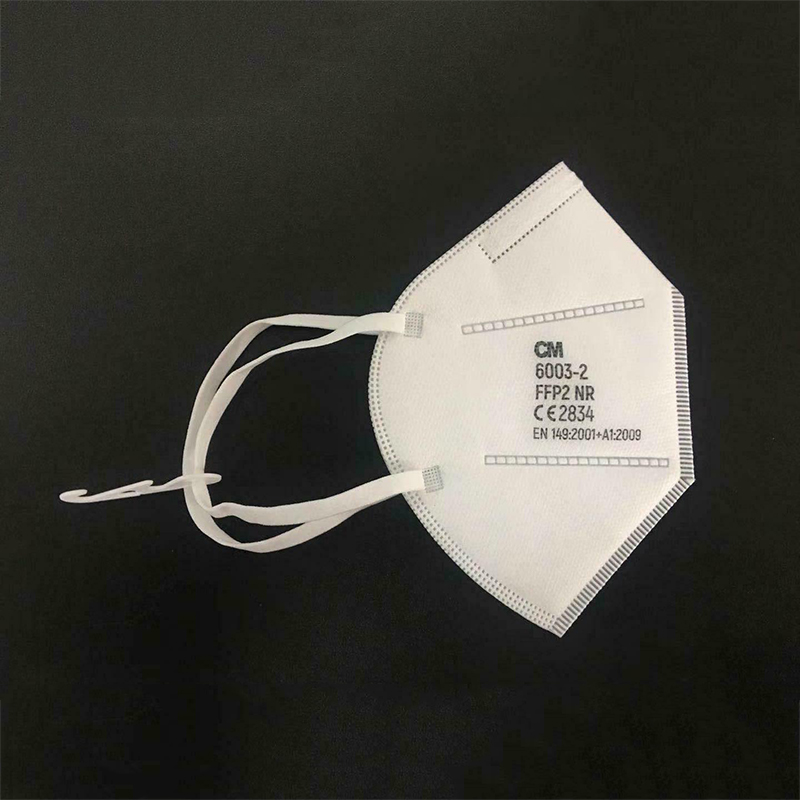

Particle filtering half mask (6003-2 FFP2)

Material composition

The surface layer is 50g non-woven fabric. The third layer is 45g hot air cotton. The third layer is 50g FFP2 filter material. The inner layer is 50g non-woven fabric.

Particle filtering half mask is a piece of personal protective equipment that is designed to fit tightly to the face and prevent airborne contaminants from being inhaled by the wearer. These devices may be called respirator or filtering facepiece respirators (FFRs).

Filtration efficiency is one of the testing methods to evaluate the mask.

Testing method- Filtration efficiency (FE)

FE is the proportion of particles that are intercepted by the filtration material. It is measured by challenging the material with particles of known size, carried at a known flow rate or velocity, and measuring the particle concentration upstream of the material, Cup, and downstream of the material, Cdown. Particle penetration through the filter material, Pfilter, is the ratio of the downstream concentration to the upstream concentration, multiplied by 100%. FE is the complement of particle penetration: FE = 100% − Pfilter. A filter material through which 5% of particles penetrates (Pfilter = 5%) has 95% FE. FE is influenced by multiple factors, including the filter material; size, shape, and charge of the challenge particles, airflow rate, temperature and humidity, loading, and other factors.

It is well known that the FE of filter material may vary for particles of different sizes and shapes. This is because filtration occurs through multiple physical processes — straining or sieving, inertial impaction, interception, diffusion, gravitational settling, and electrostatic attraction, and the efficiency of these processes varies by particle size. The particle size for which a filter material has the lowest FE is termed the most penetrating particle size (MPPS). Ideally, the MPPS is used to test filter performance, as the filter efficiency for all other particles will be better than that obtained with the MPPS. MPPS varies with filtration material and air velocity through the filter. Early studies reported MPPS for respirators of 0.3 μm, but more recent studies have shown that MPPS is in the 0.04–0.06 μm range.